Every composite door is both designed and manufactured by Rockdoor

We put a lot of time, effort, and expertise into every composite door we design, and each Rockdoor composite door is manufactured right here in the UK, in our production facility in Lancashire.

As a leading composite door manufacturer for over 25 years, we have been developing and improving our range of composite doors to make them what they are today.

It’s for this reason that we’re confident that our range of exterior doors is undoubtedly, the best composite doors on the market providing our customers with both strong and secure doors and doors that offer great thermal efficiency.

Our robust composite door manufacturing process

Discover the 9 essential steps involved in Rockdoor production. Our composite doors are manufactured using state-of-the-art technology and meticulous attention to detail to ensure that each door leaving our production facility is durable, secure, and meets all of your requirements.

- Vacuum forming – Rockdoor’s high-impact skin to achieve the authentic woodgrain

- The inner frame is created

- S-Glaze technology to secure the glass in place

- Insulating the door for the best possible Door Set Energy Ratings (DSER)

- The latest CNC technology ensures a perfect fit, every time

- Making our composite doors secure

- Customising your door to your exact requirements

- Quality control procedures

- Your brand new, bespoke-made Rockdoor is ready!

1- Vacuum forming – Rockdoor’s high-impact skin to achieve the authentic woodgrain

First of all, a high-impact skin is vacuum formed onto an intricate aluminium mould creating the durable, low maintenance grained skin in the colour of your choice. The timber effect grain on the uPVC skin really does offer the best of both worlds – it has the classic appearance of a timber entrance door but with the low maintenance benefits that only uPVC can provide.

2- The inner frame is created

Next, the inner frame of the door is constructed using rigid uPVC profiles. An aluminium-reinforced box section is then inserted into each inner frame, contributing to Rockdoors being the strongest composite doors on the UK market. Each inner frame is welded together, creating a continuous 360° ring of security.

3- S-Glaze technology to secure the glass in place

Now, it’s time for the glass to be added to the door. Unlike any other UK door manufacturers, we do not use cassettes to hold our glass in place, we use the innovative S-Glaze technology.

S-Glaze technology makes it impossible for intruders to enter your property through a window, as the glass is encapsulated in the door itself by being bonded onto the glass – locking it in for life! It also ensures no draughts between the edge of the double-glazed unit and the door itself.

4- Insulating the door for the best possible Door Set Energy Ratings (DSER)

The door then goes into a specially designed drum that injects the door with Polyurethane Foam ensuring that any gaps in the door are filled. Contributing to some of the best possible Door Set Energy Ratings available in the composite door industry.

5- The latest CNC technology ensures a perfect fit, every time

Our Computer Numerical Control (CNC) machines then trim each door to millimetre precision so that they are the exact specification for your home – it’s well known that bespoke-made doors, like ours, are significantly stronger than those that are cut to size!

These machines will also router holes for hinges, locks and letterboxes. Then, to be as environmentally responsible as possible, all waste is recycled.

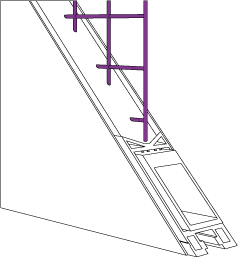

6- Making our composite doors secure

The multipoint hook locks can then be fitted to the door to ensure the sash cannot be forcibly removed from the door frame. Some door manufacturers tend to screw the locking mechanism into a timber subframe, making it easy to remove – but not at Rockdoor!

Once the Multipoint lock hook is in place, a 3-star cylinder (the best available) is used to lock the door.

7- Customising your door to your exact requirements

Next, your customisable options will be added to your new door. One of the many great things about choosing our Rockdoor for your front or back door is that it is so customisable with our extensive range of hardware.

We have a range of door knockers, letter plates and numerals, available in polished chrome, polished gold, graphite, midnight black and stainless steel.

8- Quality Control Procedures

The door then goes through a thorough inspection process, where a range of skilled technicians check absolutely every part of the door, including the glass designs, door seals and hook locks to ensure they all work perfectly.

9- Your brand new, bespoke-made Rockdoor is ready!

Finally, every composite door is robustly packaged to make its journey from our production facility to your home, so you are one step away from joining hundreds and thousands of other homeowners being protected by a Rockdoor.

If you’d like a Rockdoor installed in your home, get started today by designing your door and find a local Rockdoor installer in your area to assist you with the fitting of your new door.

Discover Our Composite Door Styles

Rockdoor Brochure and Technical Manual

For more information on our composite doors, download our Brochure and Technical Manual.

Reasons to Choose a Rockdoor

Core Benefits

Rockdoors inner strength is unsurpassed thanks to a combination of a 360° aluminium reinforced inner frame and high-density thermally efficient PU foam. Customers can also choose steel mesh reinforcing for the ultimate in security.

£2,000 Guarantee

Our lock cylinders are burglar proof. A TSOO7 3 star rating, SS 312 Sold Secure Diamond Standard and Secured by Design accreditation see to that, plus our £2,000 security guarantee.

Forced Entry

Rockdoors are designed for strength, it is in our DNA. For over 25 years, we have led the way in composite door development to ensure our doors protect homes and families from unwanted intruders and forced entry.

Hook up with Rockdoor

Strong sintered steel multi point hook locks with a 25mm throw, securely attach the door to the frame to ensure it cannot be forcibly opened by burglars whilst ensuring a better sound and weatherproof seal.

Glass Leading Security

Rockdoors feature S Glaze technology, meaning your glass is locked into your door for life, for added security. It also means no glazing cassettes are used which are prone to fading and discolouration.

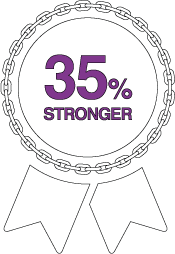

Stronger, it's Official!

Rockdoor is consistently found to be one of the most secure doors available in the UK, studies show that a Rockdoor is 35% stronger than a typical GRP door.